Description

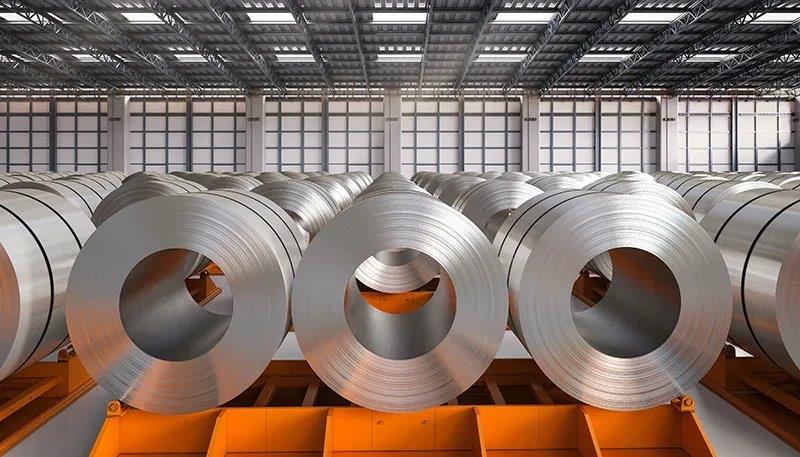

There are several types of aluminized sheets, each of which can be used for different purposes. Some are designed to resist corrosion, while others are designed to withstand extreme temperatures. The aluminum coating can also be applied to a wide range of materials such as wood, plastic, and paper.

Aluminized steel sheets are widely used in the construction industry because they are fireproof. They can be used as walls and ceiling panels, and roofing materials. They are often used to create decorative façades. Other uses include car parts, construction of machinery, building bridges, and industrial machinery.

The main advantage of using aluminized steel sheets is that they are made of corrosion-resistant material. They do not rust easily because of the aluminum coating on the steel sheet.